In-Process Inspection Services

Pro QC International provides third-party In-Process Inspections (IPI/DUPRO) in 100 countries, helping businesses detect defects early and ensure product quality during production

Pro QC International provides third-party In-Process Inspection services (IPI), also called During Production Inspection (DUPRO), in 100 countries for a large variety of product categories.

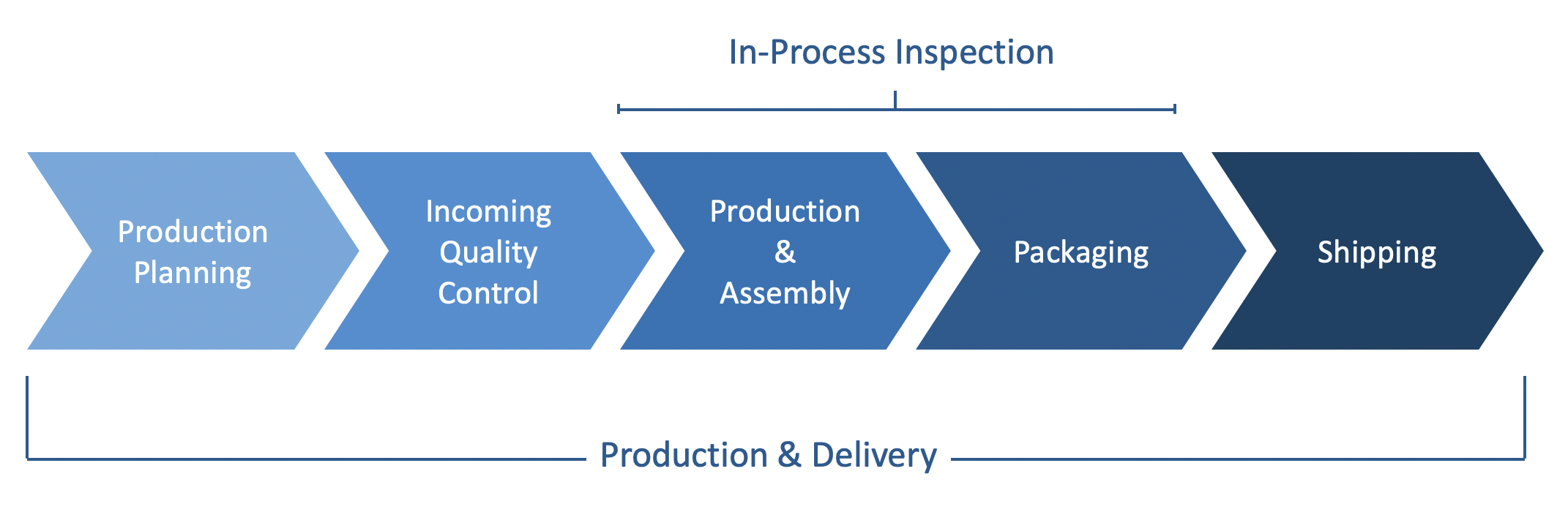

Companies need transparency and visibility into the manufacture of their products and a reassurance that final product quality will meet their requirements. In-Process Inspection serves these goals. Conducted during the production process at the most critical steps, IPI provides essential information on actual manufacturing conditions and product quality.

What is an In-Process Inspection?

An In-Process Inspection is a product inspection conducted during the manufacturing process. This control is carried out at different stages and at predetermined times. The inspection usually occurs when at least 20% of the products are completed. It provides monitoring and assurance that the factory is following established production methodology and techniques. Conducting During Production Inspections helps to identify defects at an early stage and eliminate them before products are finished, which prevents additional costs downstream.

Contact Us

Advantages of Quality In-Process Inspections

Provides an overview of all manufacturing processes

Controls production in real time

Assures superior production quality

Reduces post-production expenses

Pro QC’s In-Process Inspection Services

As a third-party quality company, Pro QC supports companies across the globe in providing impartial During Production Inspection services. Our experienced quality inspectors conduct each inspection. Inspectors are selected according to their industry experience, as knowing the manufacturing processes specific to the products to be inspected is paramount. For instance, a textile inspector will be deployed for a garment in-process inspection while a mechanical engineer will conduct a motorcycle in-process inspection.

During the service, the inspector will walk through the selected processes and follow a comprehensive inspection checklist to ensure product quality matches the specifications. Through this step-by-step process, inspectors will identify and correct any anomaly or quality defect quickly. Customers are immediately informed if there are any major or critical problems.

Ready To Control Quality?

Get started with a free consultation and discover how our quality assurance services help to meet international standards and improve quality.

Pro QC’s In-Process Inspection Reports

Our team develops customized inspection checklists according to each project. Quality inspectors follow them during the in-process inspection. The checklists typically cover:

- Quantity verification

- Visual (workmanship) evaluation

- Functional, measurement (special testing) evaluation

- Labeling verification

- Packaging verification

- Photo documentation and reporting

Pro QC’s quality control inspectors identify defects and sort them into three categories: minor, major, and critical. The inspection results are either FAIL, PENDING, or PASS. Clients receive our During Production Inspection reports within 24 hours after the service is completed and the reports include digital pictures.

Key Differentiators

- Superior industry and technical expertise garnered since 1984

- Tailored quality solutions provided in 100 countries

- Specialized and qualified quality inspectors

- Detailed inspection reports delivered within 24 hours

- Experienced with over 30,000 products from all industries

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery for Inspections

48-72 Hours

- Report Delivery for Audits

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 120 508 9113

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.